Valve intelligence

Valve intelligence

©2019 SUBITOP Intelligent Control System

©2019 SUBITOP Intelligent Control System粤ICP备17008656号-2

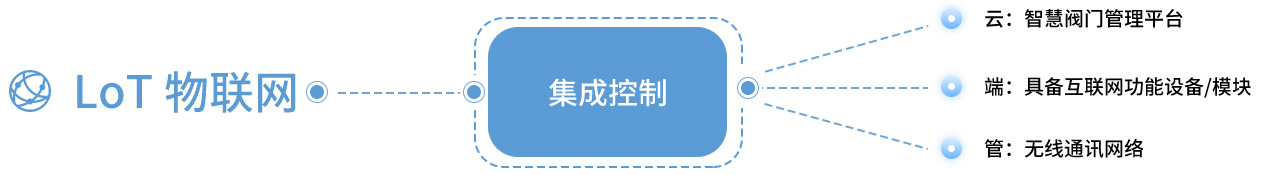

Subitop integrated control is a new system architecture. It is not a traditional concept of the Internet of things, but a new concept of "valve + Internet" built by subitop. Device awareness, cloud control, data management, big data analysis and optimization, system interdependence。

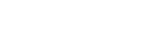

Real time control of pneumatic / electric valves with Internet of things。

10 kinds of faults such as valve over torque, locked rotor and overheat shall be forewarned, and important alarms can be prompted by SMS。

It can generate spot check plan online, upload pictures on spot check of mobile app, and dispatch automatically。

Through the web / APP cloud platform, it can access real-time data with valves, synchronously collect operation data of valves and store them for a long time。

All valves can form a management and control information system through IOT and cloud platform to realize remote IOT monitoring of all valves in the plant。

No need to lay control cables, saving more than 30% of the reconstruction cost and 70% of the construction period。

The remote monitoring platform can simultaneously monitor nearly 50 parameters, such as valve opening, feedback contact state, geographical position, alarm state, action frequency, torque curve, system temperature, etc., so as to realize real intelligent monitoring。

Through the communication network, all regional valves can be centrally monitored through a monitoring platform to break the space restrictions, which is particularly suitable for scattered areas, such as: oil pipeline, sewage plant, water plant, steel, tank farm, etc。